FRP Pipe/FRP Tank/Filament Winding Machine/Electrolytic Cell/FRP Grating Machine/FRP Pultrusion Machine

FRP electrolytic cells are widely used in electro-refining & electro-winning industry, such as Pb, Zn, Cu, Mn,and so on. Based on its good anti-corrosion and permeability resistance ability, good integrality, strong shocks resistance ability, light weight, good inner surface hardness, good smoothness, and easy to clean, it’s applied widely.

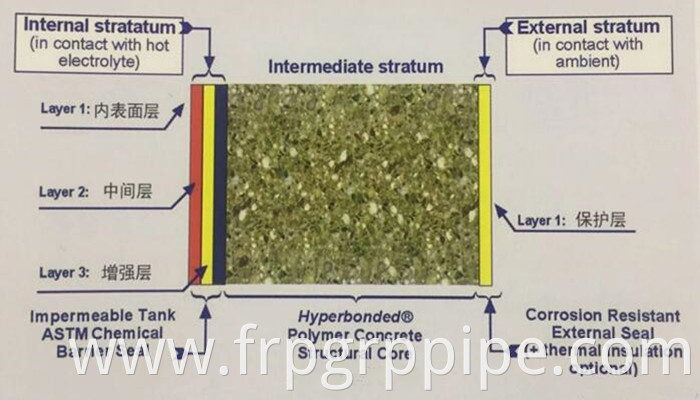

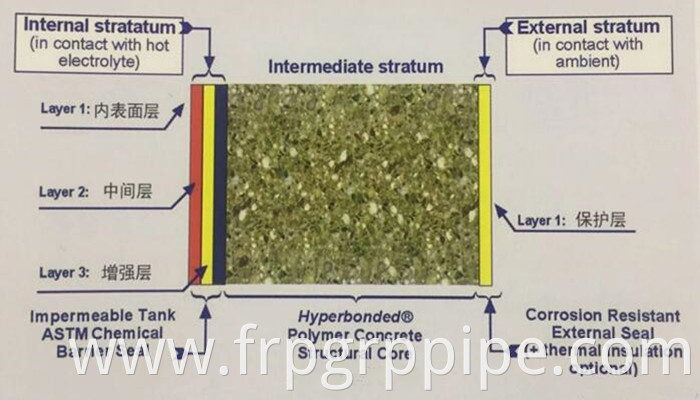

Material:

Unionsum pays critical attention on cell construction material selection to increase cell service life and decrease maintenance cost.

1.Vinyl resin from Hengshui Aoliande Trading Co., Ltd.

2.Surface mat and fiberglass from Hengshui Aoliande Trading Co., Ltd.

3.Wood/ Un-conductive magnetic steel reinforce rib inside

Production process:

Due to electrolytic cell with high anti-corrosion requirement, Unionsum will select suitable cell manufacture process according to different cell operation condition (electrolyte and temperature).

1.Optimum material composition and mould manufacture process to avoid resin gummosis phenomenon;

2.Double-side of plate manufacture synchronously, then coating with yellow gel for oxygen insulation, to increase anti-corrosion and weather resistance performance and service life.

3.Reinforced rib with FRP coating manufacture through female mould process, with good integration performance, no layer separation and cavitations between FRP and reinforcing rib, increased cell anti-deformation ability.

Structure:

Unionsum can supply the following cell types based on client requirement (loading capacity, cell inner volume,cell outer edge support span and full deformation):

1.Wood as reinforcing rib and cell bottom large rib

2.Mixed structure: Un-conductive magnetic steel as cell reinforcing rib and hoop inner rib, wood or both

3.as longitudinal reinforcing rib, wood as bottom reinforcing rib if support span ≤2000mm,steel as bottom

4.reinforcing rib if support span ≥2000mm,

5.Un-conductive magnetic steel as reinforcing rib and cell bottom large rib

Advantages:

1.Vinyl resin coating on the cell body surface(gel ≥70%).

2.Surface mat and chopped strand mat of fiber glass constitute FRP cell body.

3.Good integrality, no stitching points, horizontal and longitudinal reinforce rib with FRP coated.

4.Good strength, strong impact resistance, large loading capacity.

5.FRP density is 1.8kg/cm, lighter than polymer concrete cell.

6.Smooth and dense inner surface, easy cleaning, no pollution to anode slime.

7.Good insulation of FRP material, no transition of spurious current, no electricity leakage, high electricity efficiency.

8.Modular construction, easy transportation and saving carriage, easy installation on site.

9.Above 15 year service life, easy maintenance.