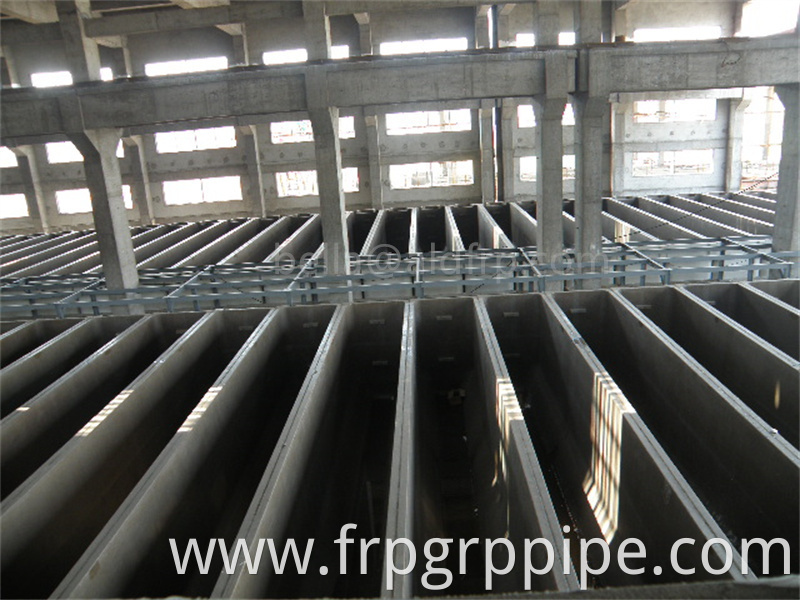

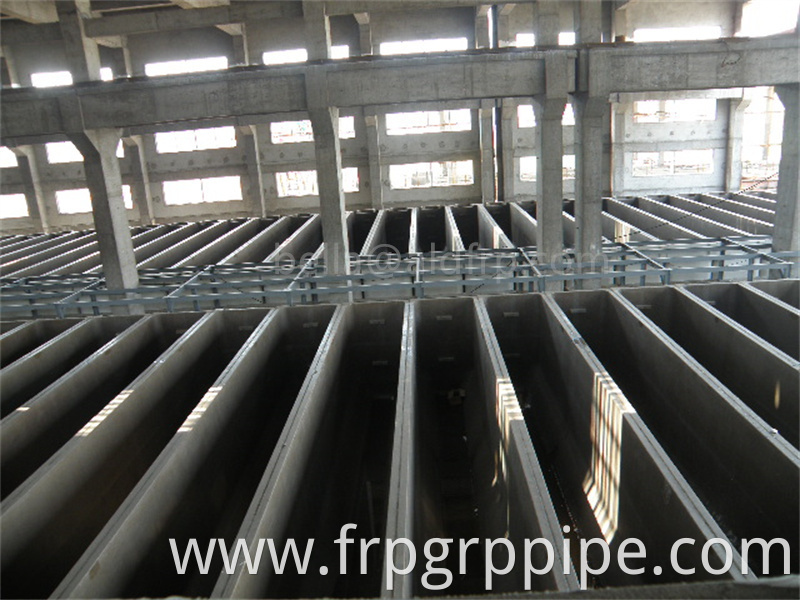

FRP Pipe/FRP Tank/Filament Winding Machine/Electrolytic Cell/FRP Grating Machine/FRP Pultrusion Machine

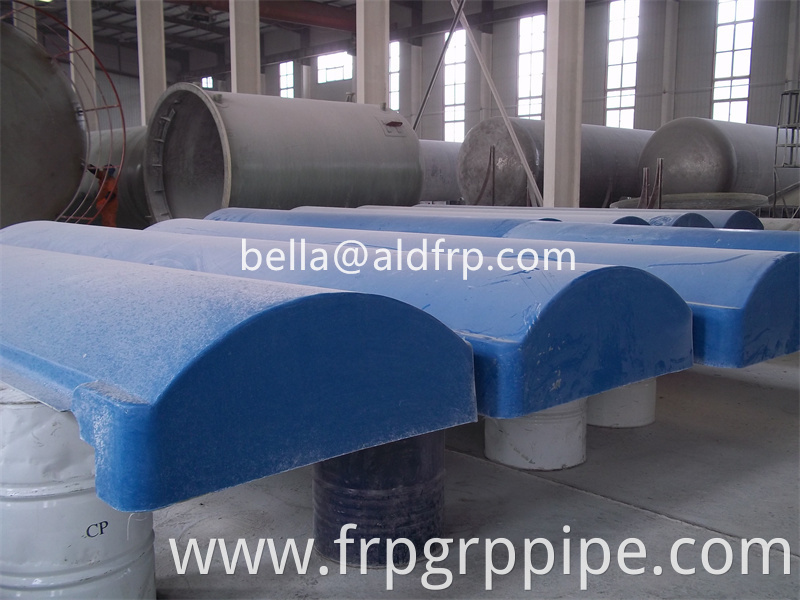

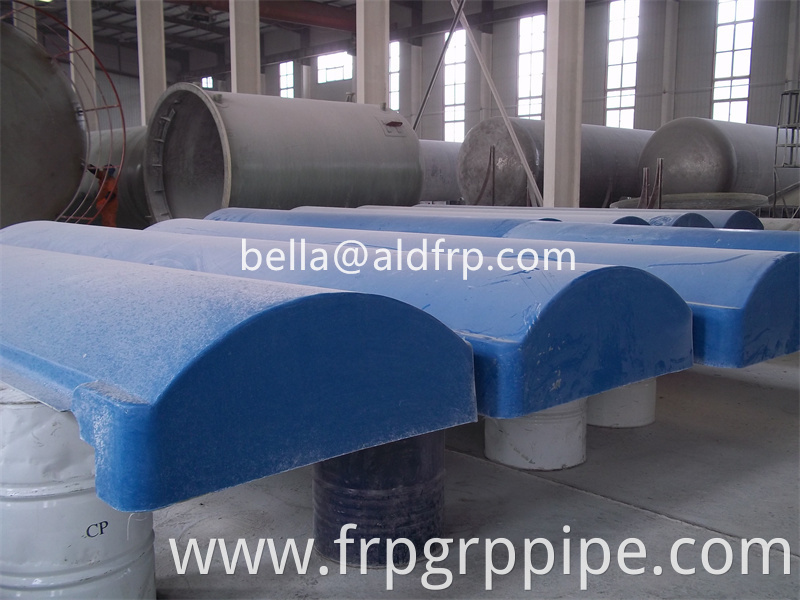

FRP electrolytic cell Design

Electrolytic cells are designed ,built and installed to satisfy the most stringent requirements rquested by tankhouse operators worldwide .In most cases their main rquest is to guarntee full operating availability throughout the plant's lifespan ,maximizing production of high-purity metal(copper,zince,nickle,cobalt,lead or other) with absolute safety for people and the environment . Additionally ,cells must accommodate changes for continuous improvement of the electrolytic process,integrating efficiently with upgrades of complementary equipment such as anodes ,cathodes ,cap boards overhead crane ,electrolte agitation system ,acid mist control devices ,thermal insulation ,among many others . Describtion Resin is the key element to FRP cell fabrication, directly influencing its service lifetime, anticorrosion resistance and mechanical strength. Fiberglass, however, determines the cell’s strength at high working temperature. The fabrication of FRP is to lay up the different fiberglass impregnated with vinyl-ester resin in sequence by hand.Metalcess ensures that the hand layup FRP is of good corrosion and leakage resistance, good strength to impact and working load, and no stitching point, smooth surface for easy cleaning. The FRP material is also good in insulation, no transition of spurious current, no electricity leakage and high electricity efficiency.As an option, the FRP layers may be pigmented white, gray or oter color favorable to refinery operation or purchaser preference.

1.Vinyl ester resin monolithic casting electrolytic cells

Electrolytic cells are designed, built and installed to satisfy the most stringent requirements requested by tankhouse operators worldwide. In most cases their main request is to guarantee full operating availability throughout the plant's lifespan, maximizing production of high-purity metal (copper, zinc, nickel, cobalt, lead or other nonferrous metals) with absolute safety for people and the environment. Additionally, cells must accommodate changes for continuous improvement of the electrolytic process, integrating efficiently with upgrades of complementary equipment such as anodes, cathodes, cap, boards, overhead crane electrolyte agitation systems, acid mist control devices, thermal insulation among many others.

2. Structure

Electrolytic cells are cast monolithically based on a patented, three-layer composite material system:

The Internal layer is a monolithic tank made with multiple layers of fiber-reinforced vinyl ester resin (FRP) complying with chemical barrier international norms that assure long-term impermeability and corrosion resistance.

The Intermediate layer is the structural core made with polymer Concrete, with a patented formulation to achieve a low coefficient of thermal expansion, providing long-term structural integrity with low thermally-induced stresses

The External layer is a standard seal layer of FRP that further protects the structural core from electrolyte splashes and spills. Optionally,this external seal may be specified with multi-layered oriented fiber reinforcements to guarantee trouble-free operation in unusually extreme operating environments.